Virtual reality

Are you familiar with the main factors that make VR training in industries faster, safer and more profitable? This article relies on proven concepts from an engineering perspective and economic knowledge. Everyone uses AI, VR and AR and this article will explain why they’re becoming a synonym with our everyday work tasks.

Table of contents

VR Training in Industries: What It Is and Why It Works

Key Benefits of VR Training: Faster, Safer, More Profitable

Why Industrial Training Is Hard (Safety, Cost, Hiring Gaps)

VR Training Capabilities for Machinery and High-Risk Tasks

CNC Machine VR Training: Preventing Errors and Reducing Downtime

Welding VR Training: Skill Development Without Toxic Exposure

Aerospace and Working-at-Height VR Training: Fear-Free Practice

Personalized VR Training for Any Machine and Manufacturer

VR Training Case Studies: Rolls-Royce and Toyota

Beyond Training: VR Monitoring and Remote Expert Support

Challenges and Limitations of VR Training in Industries

Conclusion: How VR Training Improves Industrial Performance

FAQs About VR Training in Industries

Key Takeaways

VR training helps industrial teams learn faster by compressing learning cycles through repetition, instant feedback, and measurable scoring.

VR training reduces safety risks by allowing employees to practice hazardous tasks without exposure to real machinery, toxic environments, or working-at-height scenarios.

VR training improves profitability by lowering training-related downtime, reducing damage from mistakes, and minimizing costly repairs or wasted materials.

VR training enables “trial-and-error” learning for expensive equipment like CNC machines, where real-world errors can cause jams, breakdowns, or production delays.

VR training expands the hiring pool by allowing complete beginners to learn step-by-step, lowering the barrier to entry for complex roles.

Welding VR training helps trainees build muscle memory and technique in a gas-free environment while practicing multiple joint types and real scenarios.

VR training can be customized for virtually any machine, regardless of manufacturer, making it scalable across facilities and regions.

Case studies like Rolls-Royce and Toyota show that VR training can accelerate learning, track errors, and support specialization without disrupting production lines.

Beyond onboarding, VR can support remote supervision and expert assistance, reducing travel time and enabling faster troubleshooting.

The biggest limitation isn’t capability—it’s implementation quality: comfort, realism, and clear training KPIs determine whether VR training delivers ROI.

Background

Industries, as we know, have machinery that can oftentimes be labeled as a safety hazard. That same machinery is more often than not expensive and, besides that,finding a great hire who knows how to handle the machinery with caution and efficiency is hard. So, after some time, companies like Siemens, Rolls Royce and Toyota started to train employees in VR.

VR Training Capabilities

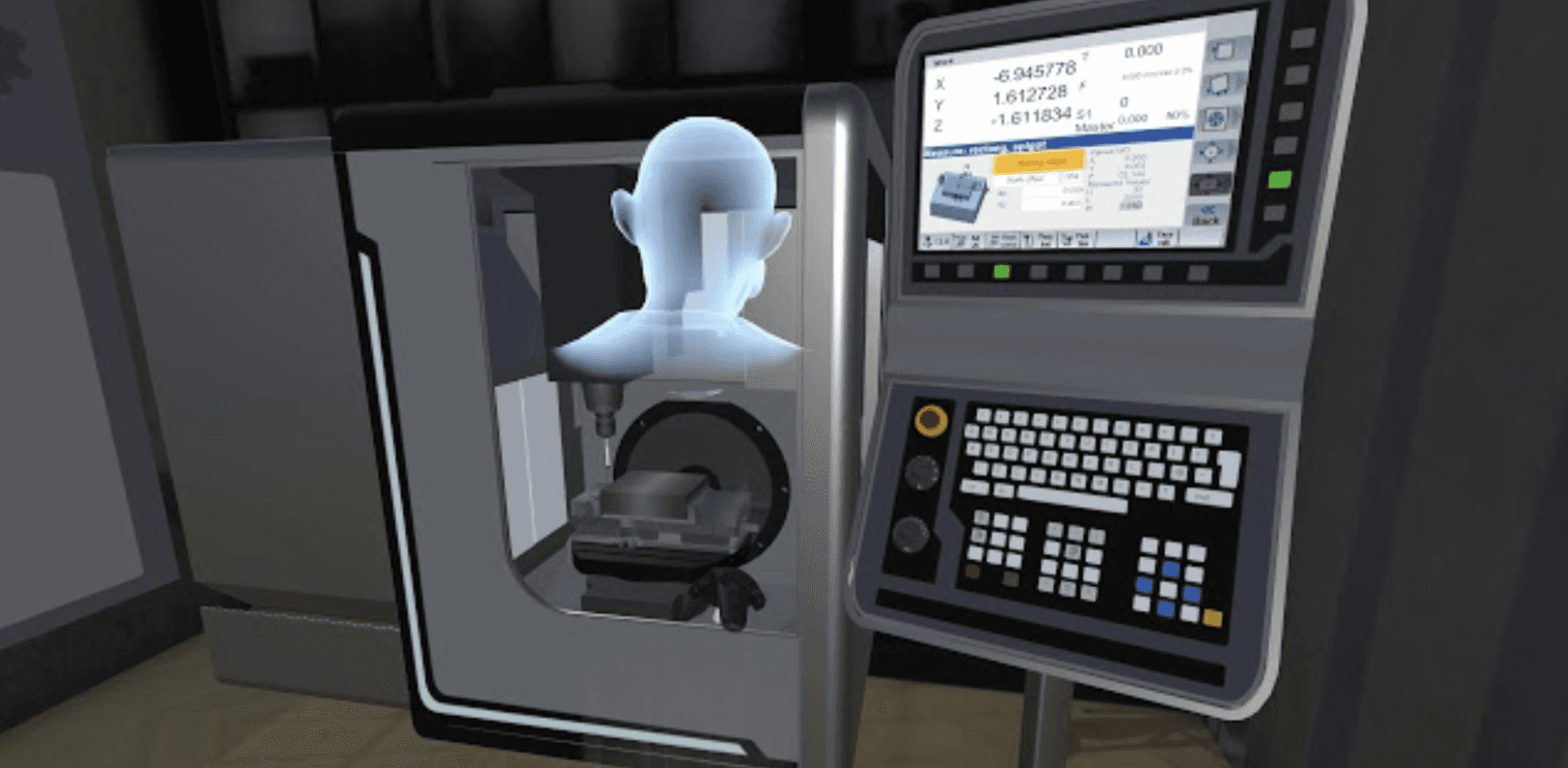

VR training has a wide range of uses-from welding training to learning how to use a CNC machine. VR training capabilities can be explained through an example of the CNC machine. A pricey, ultra-precision-cutting machine that needs human supervision and a few tweaks from an operator here and there.

One misstep or inadequate cleaning method and the machine could jam and add unnecessary expenses to the company. During VR training, a new employee can simulate the most common (and uncommon) mistakes in a repetitive cycle without the pressure of jamming or breaking the machine. In this kind of testing environment, an employee can train extensively and have ratings to see which mistakes occur.

Normally, this method is used in a way so that people unfamiliar with VR can use the experience. This ultimately leads to the conclusion that a complete beginner who does not know anything about CNC machinery can learn all the skills from the very beginning which, consequently, creates a bigger pool of potential hires for the company.

Another example is, for instance, welding training. Many people stay away from welding because of the toxic gases and an unfriendly learning curve, but it’s well known that a good weld is like art. Therefore, the potential negative repercussions of welding training can be negated by making people able to improve and learn skills in a gas-free environment in VR. Every sort of weld can be integrated into VR - from so-called Butt Joints to Corner Joints.

It should be noted that employees should not view VR training as mandatory, but as a stress-free training period. It's normal to fear some aspects of jobs, but with VR training experiences the fear is eliminated alongside the pricey repairs which would be the result of possible problems connected to mishandling the welding machine.

An example of good practice of VR training is Aerospace training, allowing a trainee to be high in the air while eliminating the element of fear. . The article Top VR apps in Aerospace shows more examples on this topic.

A key point to take into consideration is that VR experiences can be personalized for every kind of machine, regardless of the manufacturer.

Case studies and Success Stories

Rolls Royce already began maintenance training in VR. They learn about parts of the engine and components exactly as they relate to each other, either in an assembly view or while taking them apart piece by piece in the VR training experience.

Rolls Royce reported that the VR Training experience improved knowledge and accelerated the learning process of their employees by a wide margin.

Toyota created a VR training experience that would help workers to assemble and change certain car parts without needing to stop the busy process line. The experience tracks every error and gives out a score in the end encouraging time and quality in an employees’ assembly work.

Toyota has reported that it was a great success regarding new employee training and had great things to say about specialization in certain parts of their car assembly process.

Other VR uses in industries

In VR monitoring, operators track machinery and supervise if everything is running as it should be. It’s possible for a company to replace all monitors which supervise PLCs and Machinery with a VR headset and move towards more remote work. In this instance VR can increase profits by hiring a supervision specialist regardless of their location.

Example: You have an interactive VR experience, and the machine breaks down. The expert is in Germany and the broken machine is hundreds of miles away. The expert could get or buy a headset and see everything that the other person at the place sees with additional help from the assets provided in the experience (list of parts, 3D models etc.). There is no need to fly out the expert just so he can tell the company which part of the machine to order.

Challenges and Limitations

With traditional training methods, there is no room for big mistakes when working on a complicated and expensive machine. There are risks that one can't simulate for an upcoming employee.

If a significant mistake occurs, the company will need to fix the mistake (either repairing the machine or ordering a new part), which can be pretty pricey. This risk factor is eliminated by VR training experiences.

On top of that, VR training experiences can simulate catastrophic failures which (usually) don’t happen during traditional learning.

This feature can be a valuable experience for a new employee that can become more knowledgeable about other similar situations and could come up with different approaches for future problems.

Conclusion

VR training in industries is a proven concept that works and helps to increase profit margins. As VR has a wide range of uses, it can be implemented in a variety of different industries. Implementation of VR for alternative training on costly machinery or for fixing broken machinery reflects as an important financial aspect.. The best part is that one doesn’t need space or costly equipment now that headsets are broadly available. If you want to learn more about the specific data provided by companies regarding their numbers on VR training apps you can click here .As the VR industry improves and progresses it's only a matter of time before VR becomes a must-have for being competitive not only in domestic, but also in the international market.

Frequently Asked Questions

Is there something related to this case study on your mind? Take a look at some of the questions we think might interest you!

Can't find the question you are looking for?

Send us a message and we'll get back to you as soon as possible!

Latest

Take a look at our related articles

Send us a message and expect our reply as soon as possible!